As operational costs rise, organizations are looking for ways to streamline processes and satisfy customers. Manual operations are inefficient and riddled with delays. Warehouse automation has become a required investment to maintain a competitive edge, meet ever-evolving customer demands, and reduce operating costs.

“Automation positively impacts both direct and indirect operating costs, most notably by reducing manual labor, minimizing errors, streamlining processes, and increasing efficiency,” says Mark Livesay, vice president, Automated Warehousing, ESI Group.

Direct operating costs – expenses directly tied to the production of goods or delivery of services – can be positively impacted by automation that reduces or eliminates repetitive and manual tasks, performs with greater precision, maximizes machinery optimization, provides real-time tracking of inventory levels, and achieves higher and faster output rates.

Automation also saves on indirect operation costs – shared overhead expenses not directly related to production – by reducing training resources, minimizing human error, reducing unplanned maintenance, and improving data management.

Considerations for Implementation

When designing an automated warehouse, begin with a thorough analysis of your business needs and operational (historical and forecasted) data. Conduct a thorough operational assessment of current processes, including inventory flow, storage, picking, packing, and shipping. Analyze key performance indicators like throughput and error rates to establish a baseline for comparison as these factors significantly impact the best-fit automation.

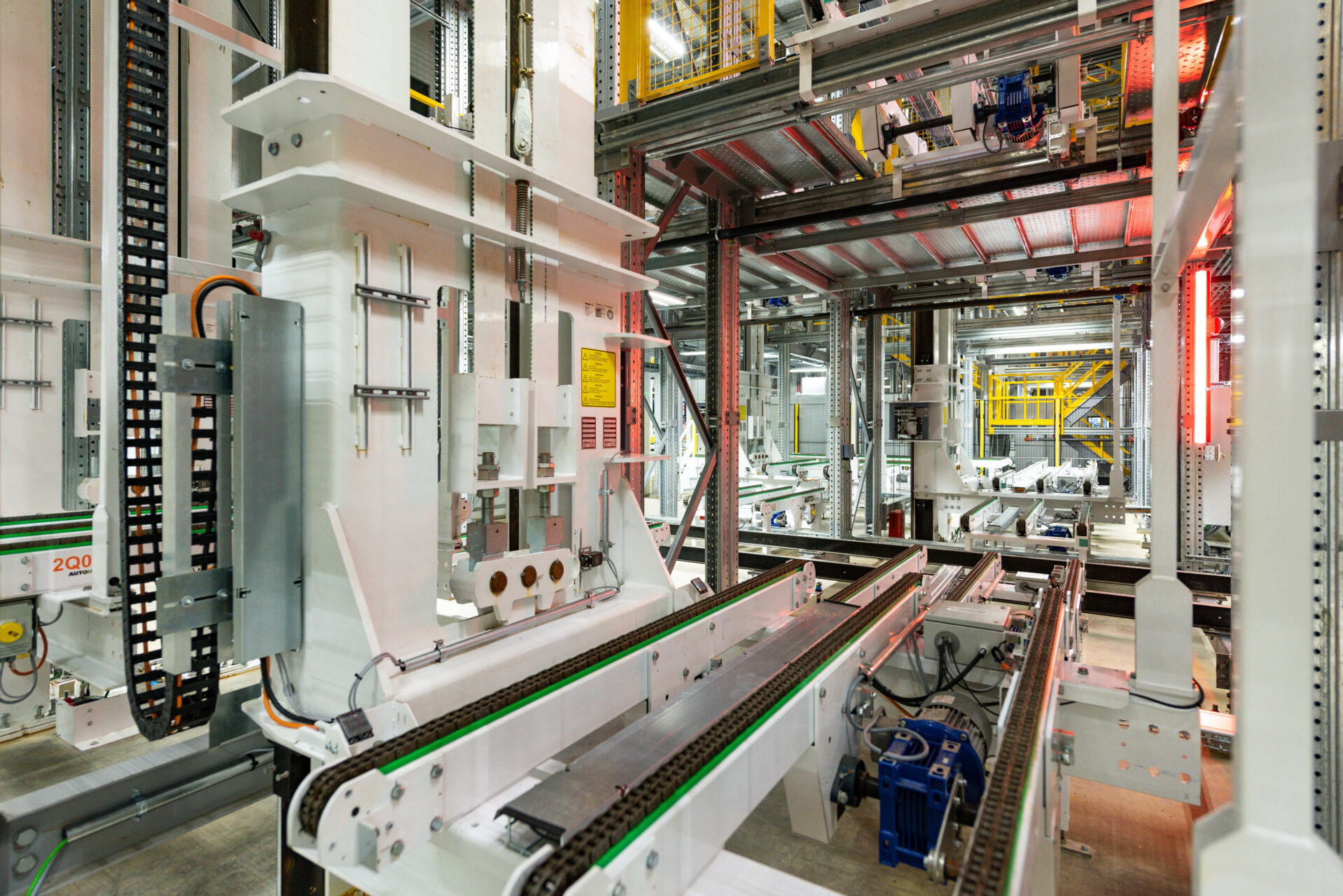

goods (Photo Courtesy ESI Group).

Anaylze key performance indicators like throughput and error rates to establish a baseline for comparison as these factors significantly impact the best-fit automation. “Automation is a strategic investment to address specific challenges, and integrating the wrong solution can create more problems than it solves,” says Livesay. Start by identifying operational inefficiencies. An automation consultant can help identify inefficiencies and even produce a computer simulation to show what type of automation would be best to achieve desired throughput results. Next, determine where the bottlenecks are and what is required to grow the business and reduce costs. For example, consider replacing outside storage warehouses with tall, automated storage and retrieval systems (AS/RS).

There will also likely be a need to integrate new automa- tion with existing systems, such as a Warehouse Manage- ment System (WMS) or Enterprise Resource Planning sys- tem (ERP). Livesay says integration is crucial for seamless data flow and optimal performance.

Additionally, choose the right technology mix. “No single technology is a silver bullet,” says Livesay. “The ideal solution may involve a blend of systems, such as Autonomous Mobile Robots for transport, AS/RS for high-density storage, and conveyor systems for high-speed sorting.”

Of course, the elephants in the room when considering automation are employee acceptance and return on investment. While automation reduces manual labor, employees still need training to operate and maintain the new technology. “Effective communication about the benefits of automation will help gain acceptance,” says Livesay. “Look beyond the initial purchase price to consider the total cost of ownership. This includes system integration, maintenance, software, and training.”

Automation requires a significant upfront investment, but the payback period can be relatively short (6 to 18 months). In some cases, ROI can take up to five years, depending on the automation, such as an AS/RS.

Operation Benefits Realized by Automation

Like ROI, quantifiable benefits from automation vary depending on the type of technology implemented, the specific industry, and the pre-automation baseline. The following documented gains should serve as examples, not guarantees:

- Near-Perfect Accuracy: Advanced automated picking systems, which use barcoding, vision systems, and ro- botics, can achieve an accuracy rate of up to 99.99%. With higher order accuracy, companies see fewer re- turns from incorrect items, which reduces costs asso- ciated with processing and restocking.

- Lower Error Rates: In manual picking, the average er- ror rate is 1%–3%, while best-in-class manual operations can get below 0.5%. Automation is key in reaching this lower rate.

- Maximize Vertical Space: AS/RS can typically save 35% for case and pallet unit load storage, and Vertical Lift Modules (VLMs) reclaim up to 85% of floor space for small items by using high-density, vertical storage. Taking advantage of ceiling height multiplies storage capacity without expanding facility footprints; layout and WMS/AI tools optimize inventory placement for even greater efficiency.

- tuses, and efficiency, enabling more accurate stock man- agement, fewer stockouts, and better decision-making.

- Increase Efficiency and Throughput: Warehouses can reduce order fulfillment from days to hours, or even minutes, with picking, sorting, and packing dramatically accelerated—many companies report 200% to 300% efficiency gains.

- Reduce Labor Costs: Automated goods-to-person systems can cut manual labor requirements by as much as 66% by reducing unproductive travel time for employees.

- Enhance Scalability and Agility: Automation provides flexibility to scale operations up or down in response to changing demands. Consumers expect faster deliveries, often within 24 hours or less.

- Preventative Maintenance: Predictive automation systems will identify faults early to avoid hundreds of minutes of annual downtime. If a failure occurs, automated workflows send alerts and speed restoration.

Achieving these operational cost savings will require partnering with a design company that has a proven track record of building automated systems. “Automation will give you a competitive advantage,” Livesay says. “In tight-margin industries like food and pharmaceuticals, even small gains in efficiency from automation can significantly impact profitability and market position.”

Quick Facts

- Automated systems lower stockouts by 30%

- Automated fulfillment reduces operational costs by up to 30%

- Food and pharma will drive automation use in cold storage to $408 billion by 2033

Join our eNewsletter

Get industry trends and insights for climate-controlled facility design and construction quarterly.